Offset Print

MORE THAN A PROCESS

Forty years of perfecting offset printing has taught us many lessons, but most importantly it’s taught us that your print project is more than just a process. When you trust us with a job, we recognize you’re placing your visual reputation in our hands—and we don’t take that responsibility lightly. We firmly believe our technical knowledge enables us to print your project as well as, if not better than, anyone else. But what will really set your experience with us apart is the personal commitment to service, quality, and satisfaction you will receive from each member of our team who works on your project, from sales to press to delivery.

OUR WORK

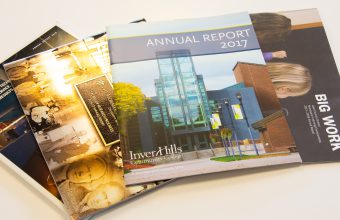

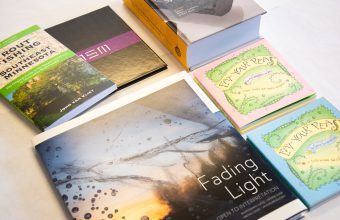

If your project calls for hundreds, or thousands, of pieces printed, with unmatched quality and clarity, then offset is your best option. We can print anything from promotional materials to catalogs to product packaging to entire books using the offset printing process, or a combination of offset and digital printing processes. Below are just a few examples of what we can do for you.

PROMOTIONAL MATERIAL

CATALOGS

MARKETING COLLATERAL

PACKAGING

POCKET FOLDERS

CARDS

ANNUAL REPORTS

BOOKS

COATINGS AND SUBSTRATES

Today, offset printing is much more than just the process of applying ink to paper. Advancements in print technology now allow us to print on a wider variety of substrates than ever before, and to add a refined touch to your project with several types of coatings. At Ideal, we’re able to print on anything from 30# paper (think tissue paper) to 36pt cover (think packaging material), that comes in a myriad of colors and textures, so that the weight of your finished project is perfect. In addition, we can help impress your audience by enhancing the sophistication of your project by applying beautiful coatings, like soft-touch (which feels like suede), or a matte aqueous coating that looks as smooth as it feels, or a more traditional gloss aqueous coating. In addition, we also provide spot high profile UV and many other special effects. Be sure to ask your sales rep for samples of coatings and substrates, to help inspire your print design.

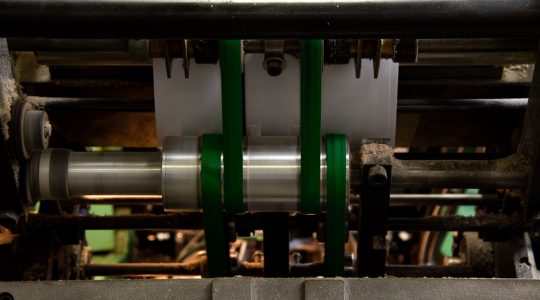

OUR OFFSET PRESSROOM

Throughout Ideal’s history, we’ve been a primarily Heidelberg shop, utilizing genuine Heidelberg sheet-fed offset printing presses. Today, Ideal Printers is still home to some of the best offset printing presses Heidelberg (and the industry) offers, in addition to specialized equipment and presses that give us expanded capability for small format print, and more unique jobs. Our facility is certified by Idealliance as a G7 Master Qualified Facility, ensuring your projects achieve visual and color consistency across all print processes.

EQUIPMENT LIST

- Heidelberg 28x40 Speedmaster fully automated CD 6-color Press (with Anilox Coater)

- Heidelberg 28x40 Speedmaster 5-color Press (with Perfecting)

- Heidelberg 28x40 Speedmaster 2-color Press (with Perfecting)

- Komori Lithrone 14x20 5-Color Press (with Aqueous Coater)

-

A.B. Dick 13x173⁄4 9810 2-color Press

-

Halm 2-color Envelope Jet Press

- Duplo 200A UV Coater

- Sun Chemical Mx12 Ink Mixing Station

- Kodak Prinergy Connect Computer-to-Plate Workflow (Electronic Prepress)

- Creo Trendsetter 800 II Quantum Computer-to-Plate System (Electronic Prepress)

- G7 Color Management Certified

ABOUT THE OFFSET PROCESS

At Ideal Printers, offset lithographic printing (or ‘offset’ for short) is the backbone of our printing operation, and a process we have perfected since our doors opened in 1979. Like many people, you probably have one question—what in the world is ‘offset lithographic printing’? At its core, it’s a printing process that revolves around the principle that water and ink (vegetable oil-based) don’t mix. Here’s a quick rundown:

To start, image information is laser-etched onto a thin metal plate. This plate is then loaded onto a print cylinder inside of the printing press. With each revolution of this cylinder, the plate passes under a water roller, which wets the non-image area of the plate, and ink roller, which applies ink to the image area. The ink on the image area of the plate is then transferred (or offset) as a mirror image onto a rubber blanket cylinder, which is then transferred (as a right-facing image), to the substrate or printing surface—like paper.

To achieve full color printing, this process occurs four or more times (each metal plate contains different etchings for cyan, yellow, magenta, and black inks, plus any specialty colors in your design). The result is stunning, crisp, and beautiful print, that is unmatched by any other printing process.